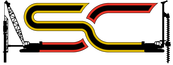

Augercast

|

In the appropriate soil profile, augercast pile is an economic alternative to traditional high-capacity deep foundations. Augercast piles cause minimal ground disturbance and are often used for noise and environmentally sensitive sites. These piles are typically best suited for ground conditions consisting of sands and silts below the water table.

An augercast pile, also known as a CFA pile, is formed by drilling into the ground with a hollow stemmed continuous flight auger to the required depth or degree of resistance. No casing is required. A high slump concrete mix is then pumped down the stem of the auger. While the concrete is pumped, the auger is slowly withdrawn, lifting the spoil on the flights. A shaft of fluid concrete is formed to ground level. Then a pile rebar cage can be placed into the still-fluid shaft to provide additional strength. Advantages of Augercast Piles:

|

Sheet Pile

|

Unlike bearing piles, sheet piles are considered retaining piles. They are special shapes of interlocking piles made of steel, wood, or concrete which form a continuous wall to resist horizontal pressures resulting from earth or water loads. Sheet Pile Applications:

|

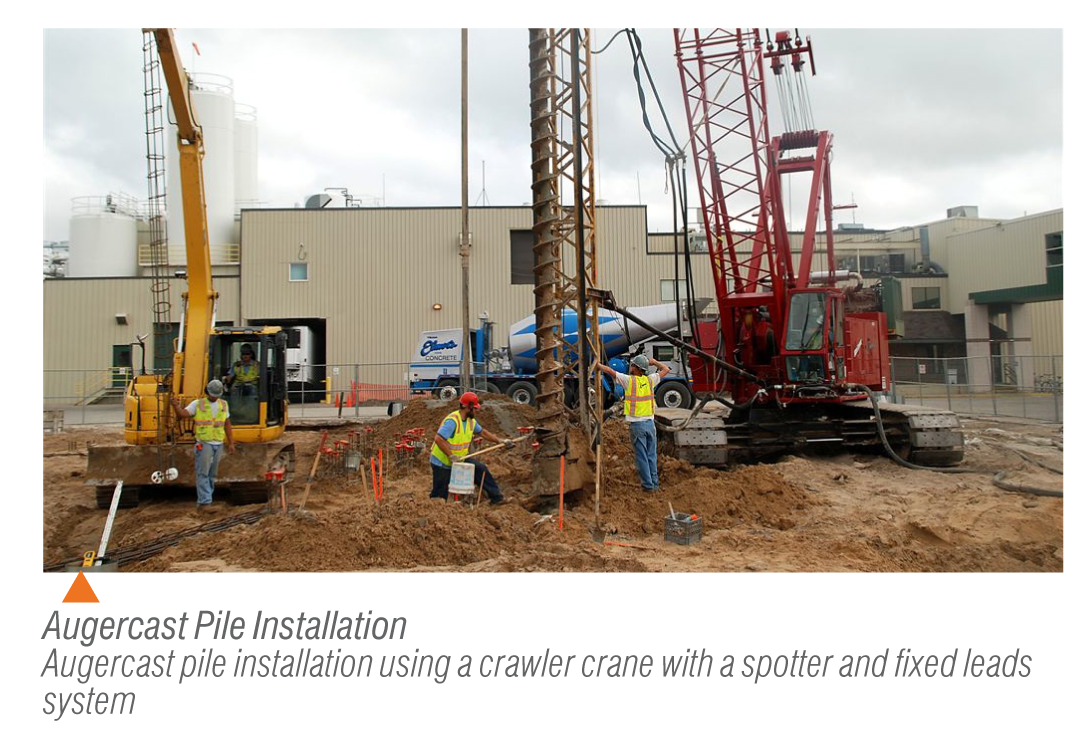

Soldier Pile & Lagging Wall

|

Soldier pile and lagging walls are commonly

used systems for supporting excavations in urban environments where property lines, roads, and utilities prohibit sloped or benched excavations. The main components of soldier pile and lagging excavation support systems are steel H-piles placed vertically from 4 to 10 ft. on center with lagging placed between the piling to retain the soil. Once the H-piles are installed, excavation can proceed. As the excavation is advanced, lagging is placed between the soldier piles. The lagging may consist of rough sawn timber, metal decking, or even pre-cast concrete planks. The stability of the wall is dependent on earth pressure that is being resisted by pressure on the inserted section of the pile. Advantages of Soldier Pile & Lagging Walls:

|

|

Installation Methods:

SC has the expertise and capabilities of installing H-piles in a wide range of different soil conditions. We also have the know-how to install piles in environmentally sensitive areas, projects with difficult access and in locations where there are noise and vibration constraints. I. Impact Driving

II. Vibrating the Piles

III. Pre-Drill and Grout the Piles

|

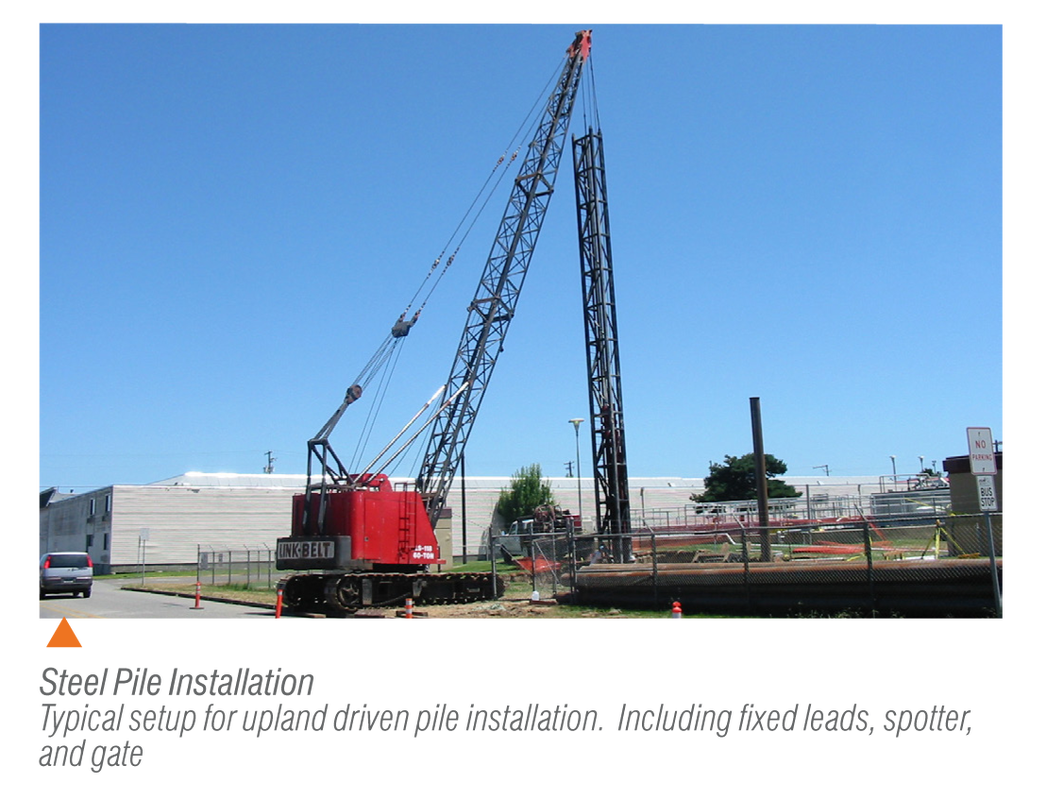

Driven Pile Foundation

|

Subsurface construction specializes in driven pile foundations to provide the necessary support for even the largest construction projects. Typically, driven pile foundations are recommended when there are large design loads, poor soil at shallow depths, or due to site constraints.

Driven Pile Applications:

|

|

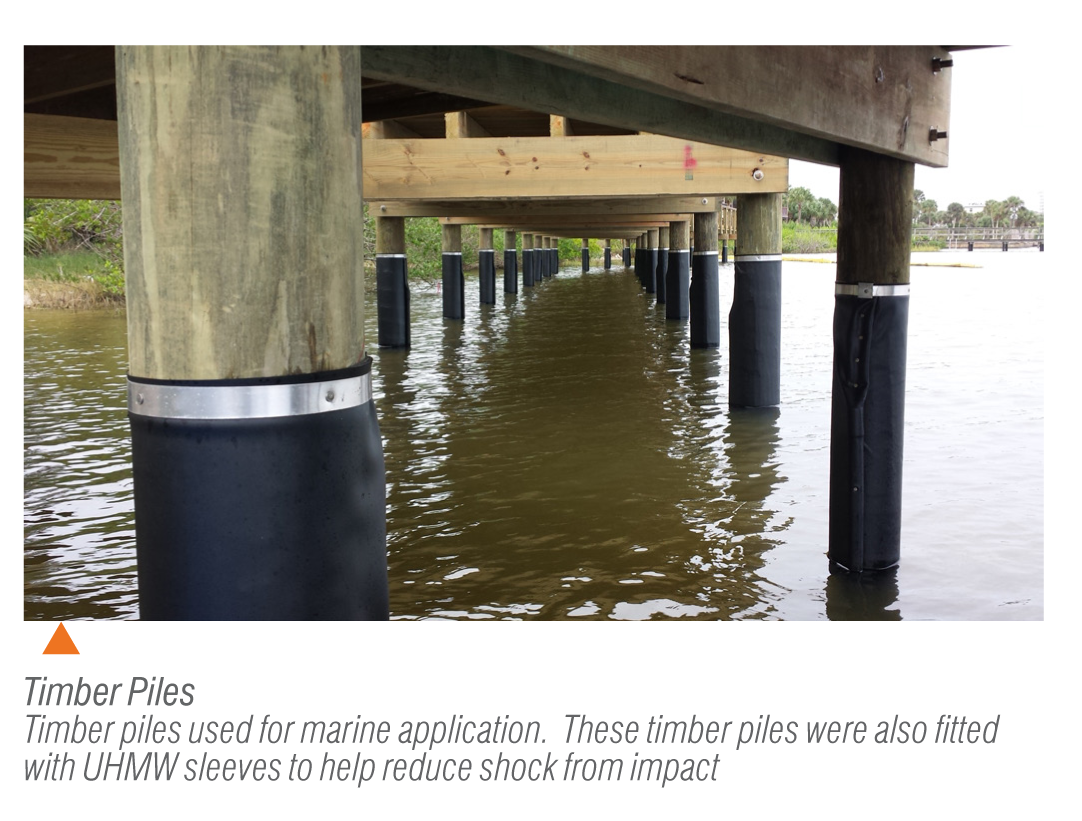

I. Timber Piles:

|

|

II. Steel Piles:

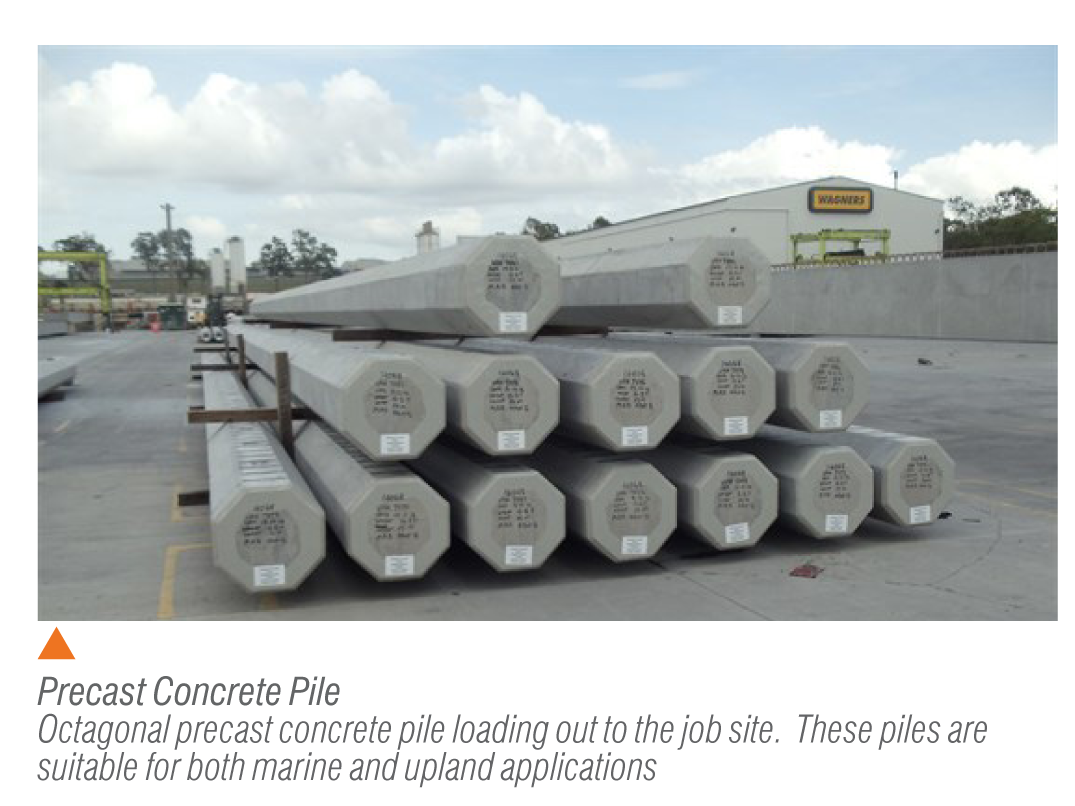

III. Precast Concrete Piles:

|

Marine Construction

|

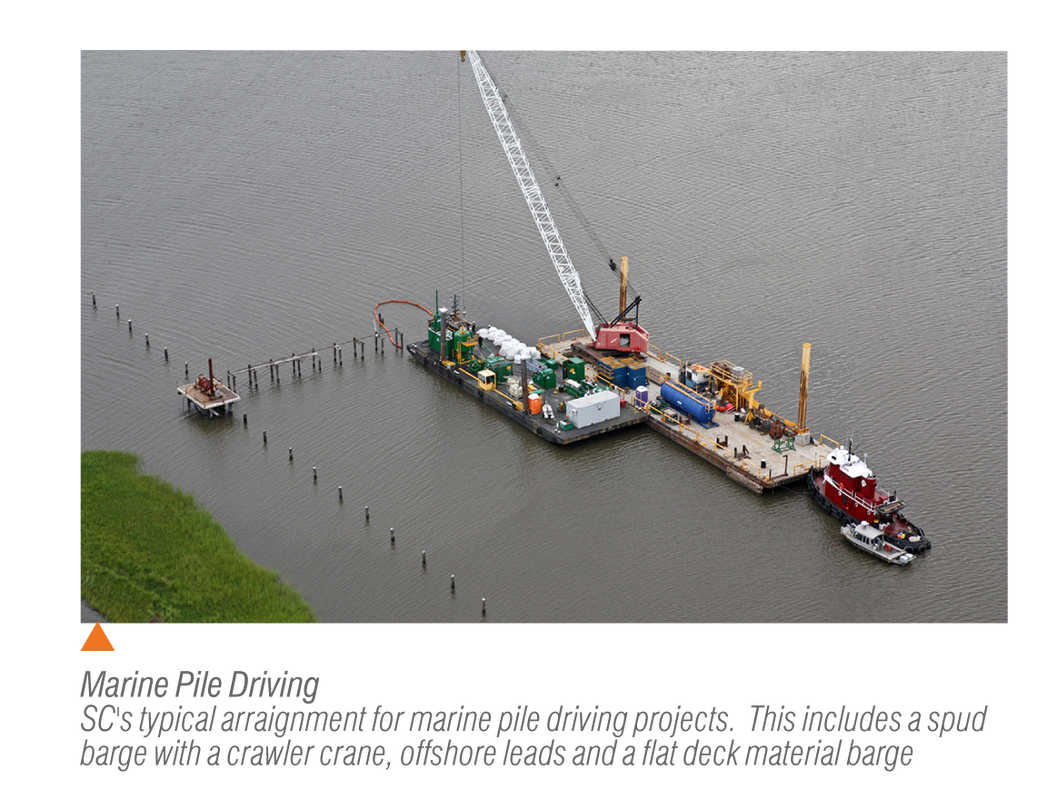

MARINE PILING AND MARINE SUPPORT:

Marine construction is at the heart of Subsurface Construction excellent track record. Our company has extensive experience in all aspects of marine construction from building docks and ferry terminals to deep foundation and offshore pile driving. Additionally, our crews are experts in barge and anchor handling. We provide and operate barges to safely assist in marine construction projects. Marine Services Include:

|